Salford AB200DSM APPLICATOR FOR JOHN DEERE

The industry’s largest and most efficient pneumatic applicator is equipped with an 80’ air boom that beats the competition by 14% in application width. The AB200DSM is engineered for the latest generation of Deere® 600R high clearance chassis and compatible with the 600R’s greater hydraulic capacity and fully integrates with the Greenstar® 4600 Command center with Spreadstar™ rate control. The self...

- Overview

- Specifications

- Gallery

- features

- product specs

- materials spread

- detailed equipment specifications

- hopper

- metering and drive

- tires and axles

- monitoring and precision control

- literature

- Videos

Overview

|

The industry’s largest and most efficient pneumatic applicator is equipped with an 80’ air boom that beats the competition by 14% in application width. The AB200DSM is engineered for the latest generation of Deere® 600R high clearance chassis and compatible with the 600R’s greater hydraulic capacity and fully integrates with the Greenstar® 4600 Command center with Spreadstar™ rate control. The self-propelled applicator is available with a two-compartment hopper to maximize application options and precision and the patented row crop boom can be equipped with application drop tubes on 30-inch centers. |

Specifications

Gallery

features

|

The AB200DS2 has an 80-foot working width, engineered for stability at high operating speeds, spanning 14% more than the next largest pneumatic applicator available on the market. Air booms and funnels are factory calibrated. This makes for incredibly accurate application in the widest range of conditions. The hydraulic boom suspension allows for greater in-field stability at higher operating speeds. The boom height can also be manually controlled by the operator to improve contouring in uneven terrain. The AB200DS has a higher, 69-inch boom clearance for post-emergence application later in the growing season and can be paired with optional drop tube kit on 30-inch centers for application in standing row crops. |

|

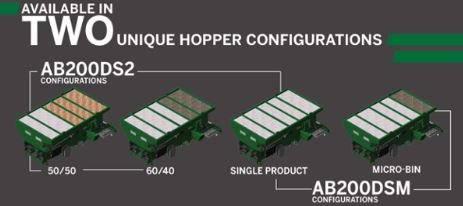

Model year 2023 AB200DS applicators are available with two unique hopper configurations. Either configuration allows for a single product or two product application and can be useful for applying different treated products. With the AB200DS2, the operator can fill the hopper with one product, or can fill two products in either a 50/50 or 60/40 split. The bin partitions have independent metering, allowing for variable rate application. |

|

The AB200DS hopper can be equipped with an electrically controlled tarp. The tarp can be opened and closed from within the cab using controls in the GreenStar 4600 CommandCenterTM or can be operated using the wireless remote included with the system. |

|

Prescription variable rate control is handled through the GreenStar 4600 CommandCenterTM. With the integrated SpreadStarTM software, operators get a simple and intuitive interface. Left and right sections can be operated manually through the multi-function handle or automatically using sectional control. Fan on and off is activated through the CommandARMTM and uses PWM control through the SpreadStarTM controller. |

product specs

|

Series |

Valmar |

|

Size |

215 cu-ft |

|

Product type |

Chassis Mount Air Boom Applicators |

|

Model Name Short |

AB200DSM |

|

Model Name Long |

AB200DSM Applicator for John Deere High Clearance Chassis |

materials spread

|

Fertilizer |

Yes |

|

AG Lime |

No |

|

Litter |

No |

|

Organics |

No |

|

Seed |

Yes |

|

Other |

Granular Herbicide |

|

Number of products applied, including optional hopper compartments |

2 |

detailed equipment specifications

|

Paint |

Green |

|

Hitch |

N/A |

|

Jack |

N/A |

|

Tarp |

Standard: No Tarp |

|

Tail Light |

Transport lighting and external LED work lights |

|

Height |

81" Unmounted |

|

Weight |

9,360 lbs |

hopper

|

Hopper Size |

215 cubic foot 2 compartment hopper |

|

Hopper Material |

Standard: 409 Stainless Steel, Painted |

|

Hopper Extensions |

N/A |

|

Hopper Gate Control |

N/A |

|

Hopper Ladder |

∙ Front ladder & platform |

|

Hopper "Inverted V" |

Yes |

|

Hopper Sight Window |

Yes |

metering and drive

|

PTO Drive |

Chassis Supplied |

|

Material Distribution Booms/Spinners/Air Line |

∙ 80 foot spread / 304 stainless steel |

|

Application Swath Width |

80 feet |

|

Material Distribution Drive |

17 inch S3 fan with pwm control |

|

Metering Drive |

Hydrualic driven metering via chassis supplied hydraulics |

|

Primary Metering |

Dual 14″ 304 stainless steel mesh chain conveyors (1 LH & 1 RH) |

|

Primary Metering Minimum Output Rate |

95 lbs/acre* at 10 mph, 65 lbs/cu-ft |

|

Primary Metering Maximum Output Rate |

750 lbs/acre* at 10 mph, 65 lbs/cu-ft |

|

Secondary Metering |

Optional: Roller Meter System for Micro-Nutrient Compartment |

|

Secondary Metering Minimum Output Rate |

Low Pegged Roller: 5 lbs/acre* Standard Pegged: 15 lbs/acre* |

|

Secondary Metering Maximum Output Rate |

Low Pegged Roller: 75 lbs/acre* Standard Pegged: 275 lbs/acre* |

|

Material Banding or Section Control |

Left/Right |

tires and axles

|

Axle |

- |

|

Tire and Wheel Options |

- |

monitoring and precision control

|

Monitors Options and Rate Control |

- |

|

Weigh System Option |

- |

literature

| Name | Link |

| John Deere AB200DS Literature | Download |